Exploring the ultimate performance of high temperature plate exchange refrigerated dryer

Release Time : 2025-03-04

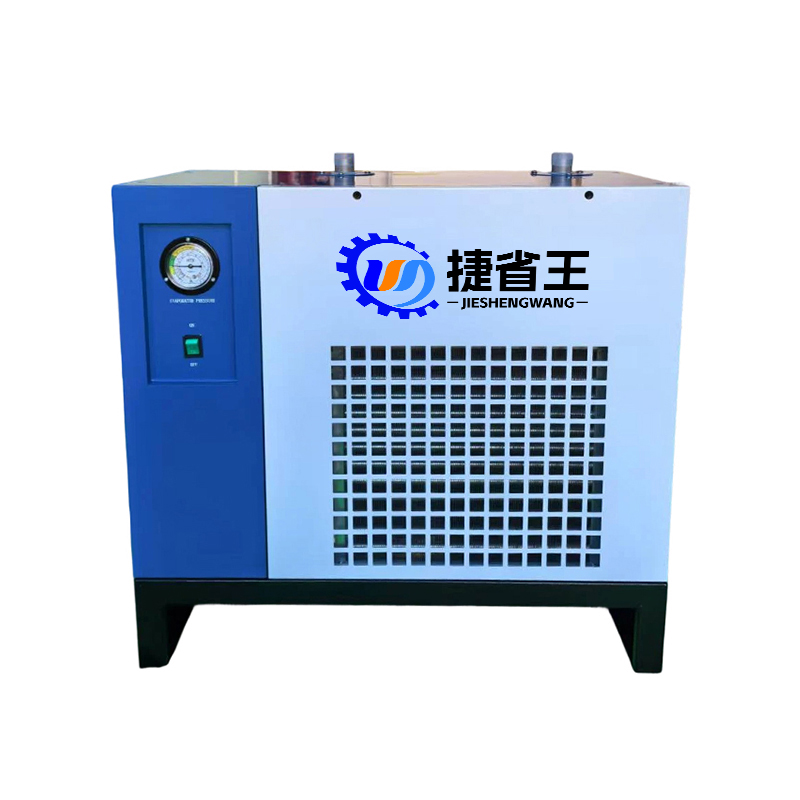

Exploring the ultimate performance of high temperature plate exchange refrigerated dryer requires in-depth analysis from multiple aspects such as its working principle, design features, and application advantages.

1. Working principle and design features

High temperature plate exchange refrigerated dryer mainly uses plate heat exchanger for heat exchange. By reducing the temperature of compressed air to below the dew point, the water vapor in the air is condensed into liquid water and discharged, thereby achieving the purpose of drying. Its design features are mainly reflected in the following aspects:

Efficient plate heat exchanger: Using a three-in-one aluminum plate-fin heat exchanger, this design makes the heat transfer efficiency higher, the energy consumption lower, and the structure more compact. The plate heat exchanger can make full use of the cooling capacity and improve the heat exchange efficiency, thereby ensuring that the performance of the dryer reaches the extreme.

Optimized refrigeration system: Compared with the traditional shell and tube cold dryer, the high temperature plate exchange refrigerated dryer can achieve energy saving of about 30% under the same processing capacity. This is due to its optimized refrigeration system, which makes energy consumption lower and efficiency higher.

Reliable separator and automatic electronic drain valve: ensure that liquid water is separated and discharged to avoid secondary pollution of compressed air, while improving the stability and reliability of the equipment.

Industrial-grade imported motor refrigeration compressor: stable operation, low noise, reliable performance, power saving and long life, providing a strong guarantee for the ultimate performance of high temperature plate exchange refrigerated dryer.

2. Application advantages

High temperature plate exchange refrigerated dryer shows excellent application advantages in many aspects:

High efficiency and energy saving: Due to its optimized refrigeration system and efficient plate heat exchanger, energy consumption is lower and efficiency is higher. This not only reduces production costs, but also meets the needs of modern environmental protection.

Stable and reliable: The use of high-quality materials and advanced manufacturing processes makes the equipment have high stability and reliability. Even in harsh environments, it can operate stably and meet various gas needs.

Small footprint: compact design, small footprint, especially suitable for installation in places with limited space. This provides users with more choices and convenience.

Easy operation: The new intelligent controller integrates dew point display and fault alarm functions, making the operation easier and more intelligent. Users can easily grasp the operating status of the equipment and make corresponding adjustments and maintenance.

3. Application fields

High temperature plate exchange refrigerated dryer has been widely used in many fields due to its unique advantages and excellent performance:

Pharmaceutical industry: The quality requirements for compressed air are high, and high temperature plate exchange refrigerated dryer can meet these requirements to ensure the normal operation of the production line and the stability of product quality.

Food processing industry: In the process of food processing, it is necessary to ensure the dryness and cleanliness of compressed air. High temperature plate exchange refrigerated dryer can provide high-quality dry air to meet the needs of food processing.

Electronic industry: The quality and stability requirements for compressed air are high, and high temperature plate exchange refrigerated dryer can provide a stable and reliable supply of compressed air to ensure the normal operation of the production line and the stability of product quality.

Aerospace field: There are extremely high requirements for the dryness and stability of compressed air. High temperature plate exchange refrigerated dryer can meet these requirements and provide high-quality compressed air for the aerospace field.

In summary, high temperature plate exchange refrigerated dryer has been widely used and recognized in many fields for its unique advantages and excellent performance such as high efficiency and energy saving, stability and reliability, small footprint, and easy operation.

1. Working principle and design features

High temperature plate exchange refrigerated dryer mainly uses plate heat exchanger for heat exchange. By reducing the temperature of compressed air to below the dew point, the water vapor in the air is condensed into liquid water and discharged, thereby achieving the purpose of drying. Its design features are mainly reflected in the following aspects:

Efficient plate heat exchanger: Using a three-in-one aluminum plate-fin heat exchanger, this design makes the heat transfer efficiency higher, the energy consumption lower, and the structure more compact. The plate heat exchanger can make full use of the cooling capacity and improve the heat exchange efficiency, thereby ensuring that the performance of the dryer reaches the extreme.

Optimized refrigeration system: Compared with the traditional shell and tube cold dryer, the high temperature plate exchange refrigerated dryer can achieve energy saving of about 30% under the same processing capacity. This is due to its optimized refrigeration system, which makes energy consumption lower and efficiency higher.

Reliable separator and automatic electronic drain valve: ensure that liquid water is separated and discharged to avoid secondary pollution of compressed air, while improving the stability and reliability of the equipment.

Industrial-grade imported motor refrigeration compressor: stable operation, low noise, reliable performance, power saving and long life, providing a strong guarantee for the ultimate performance of high temperature plate exchange refrigerated dryer.

2. Application advantages

High temperature plate exchange refrigerated dryer shows excellent application advantages in many aspects:

High efficiency and energy saving: Due to its optimized refrigeration system and efficient plate heat exchanger, energy consumption is lower and efficiency is higher. This not only reduces production costs, but also meets the needs of modern environmental protection.

Stable and reliable: The use of high-quality materials and advanced manufacturing processes makes the equipment have high stability and reliability. Even in harsh environments, it can operate stably and meet various gas needs.

Small footprint: compact design, small footprint, especially suitable for installation in places with limited space. This provides users with more choices and convenience.

Easy operation: The new intelligent controller integrates dew point display and fault alarm functions, making the operation easier and more intelligent. Users can easily grasp the operating status of the equipment and make corresponding adjustments and maintenance.

3. Application fields

High temperature plate exchange refrigerated dryer has been widely used in many fields due to its unique advantages and excellent performance:

Pharmaceutical industry: The quality requirements for compressed air are high, and high temperature plate exchange refrigerated dryer can meet these requirements to ensure the normal operation of the production line and the stability of product quality.

Food processing industry: In the process of food processing, it is necessary to ensure the dryness and cleanliness of compressed air. High temperature plate exchange refrigerated dryer can provide high-quality dry air to meet the needs of food processing.

Electronic industry: The quality and stability requirements for compressed air are high, and high temperature plate exchange refrigerated dryer can provide a stable and reliable supply of compressed air to ensure the normal operation of the production line and the stability of product quality.

Aerospace field: There are extremely high requirements for the dryness and stability of compressed air. High temperature plate exchange refrigerated dryer can meet these requirements and provide high-quality compressed air for the aerospace field.

In summary, high temperature plate exchange refrigerated dryer has been widely used and recognized in many fields for its unique advantages and excellent performance such as high efficiency and energy saving, stability and reliability, small footprint, and easy operation.